Well Grout & Annular Seals: California Requirements & Repair Guide

Published February 1, 2026 | 10 min read

Your well's annular seal is the invisible barrier protecting your drinking water from contamination. When well grout is properly installed, it creates a watertight seal that prevents surface pollutants, bacteria, and contaminated groundwater from entering your water supply. When it fails, the consequences can range from recurring water quality problems to serious health risks. This guide explains everything California well owners need to know about well grouting, annular seals, and well seal requirements.

What Is Well Grout?

Well grout is a sealing material—typically cement-based or bentonite clay—that fills the space between your well casing and the drilled borehole. This space, called the annular space or annulus, would otherwise create a direct pathway for contamination to reach your aquifer.

When a well is drilled, the borehole is slightly larger than the casing that's installed inside it. Without proper well grouting, this gap acts like a highway for surface water, agricultural runoff, septic effluent, and other contaminants to travel downward along the outside of your casing—bypassing all the natural filtration that normally protects groundwater.

Key Terms

- Annular space: The gap between the well casing and the borehole wall

- Annular seal: The grout material filling and sealing this space

- Well grout: Cement, bentonite, or approved sealing material

- Surface seal: The uppermost portion of the annular seal at ground level

Why Proper Well Grouting Matters

The annular seal serves as your well's primary defense against contamination. Here's what proper well grouting protects against:

Surface Water Contamination

Rainwater, irrigation runoff, and floodwater can carry bacteria, pesticides, fertilizers, and other pollutants. Without an intact annular seal, these contaminants can flow directly into your aquifer along the outside of the casing. This is especially dangerous during heavy rains when surface contamination is highest.

Cross-Contamination Between Aquifers

Many properties have multiple water-bearing zones at different depths. A proper well grout seal prevents water from a shallow, potentially contaminated aquifer from mixing with deeper, cleaner water supplies. This is particularly important in agricultural areas where shallow groundwater may contain nitrates or other contaminants.

Septic System Protection

Septic leach fields and cesspools can contaminate shallow groundwater. The annular seal prevents this contaminated water from traveling down to your well's intake depth. California requires minimum setback distances between wells and septic systems, but the grout seal provides additional protection.

The Hidden Danger

A compromised annular seal often shows no visible signs above ground. Your well may appear perfectly normal while contaminants silently travel down the outside of the casing. This is why recurring bacterial contamination or unexplained water quality changes should prompt an investigation of your well's seal integrity.

California Well Grout Requirements

California has specific well seal requirements established in the California Well Standards (Bulletin 74-81 and 74-90) and enforced by local agencies. Understanding these requirements helps ensure your well is properly protected:

Minimum Seal Depth

The annular seal must extend from the ground surface to a minimum of 50 feet, or to the top of the first impervious stratum below the water table—whichever is less. In practice, most wells in San Diego and Riverside counties require the full 50-foot seal due to local geology.

Local Agency Requirements

County environmental health departments or water districts may impose stricter requirements based on local conditions. Areas with known contamination, agricultural activity, or sensitive aquifers often require deeper seals or specific grout materials. Always check with your local enforcing agency before well construction or repair.

Installation Standards

California well standards specify that:

- Grout must be placed by tremie pipe (pumped from the bottom up), not poured from the surface

- The annular space must be at least 1.5 inches wide for proper grout placement

- Grout must be continuous with no voids or gaps

- The surface seal must slope away from the casing to prevent ponding

- A concrete pad or sanitary seal is required at the surface

Types of Well Grout Materials

Several materials are approved for well grouting in California, each with specific advantages:

Neat Cement Grout

A mixture of Portland cement and water, neat cement grout is the traditional choice for well sealing. It provides excellent structural strength and creates a permanent seal. The standard mix uses about 5-6 gallons of water per 94-pound bag of cement.

Best for: Most standard well installations, hard rock formations

Consideration: Shrinkage during curing can create micro-cracks; additives can reduce this

Bentonite Grout

Bentonite is a natural clay that swells when hydrated, creating a tight seal. It's available as chips, pellets, or pumpable slurry. Bentonite grout is self-healing—if minor cracks develop, the clay swells to reseal them.

Best for: Areas where ground movement is expected, deeper seals, situations requiring flexibility

Consideration: Can dry out and shrink if water table drops significantly

Cement-Bentonite Mixtures

Combining cement with 3-5% bentonite creates a grout with the strength of cement and the flexibility and self-healing properties of bentonite. This is increasingly the preferred material for critical sealing applications.

Best for: Most applications, especially where long-term seal integrity is critical

Consideration: Slightly more expensive than neat cement alone

Signs of Annular Seal Failure

Recognizing the warning signs of grout failure can prevent serious contamination problems. Watch for these indicators:

Water Quality Changes

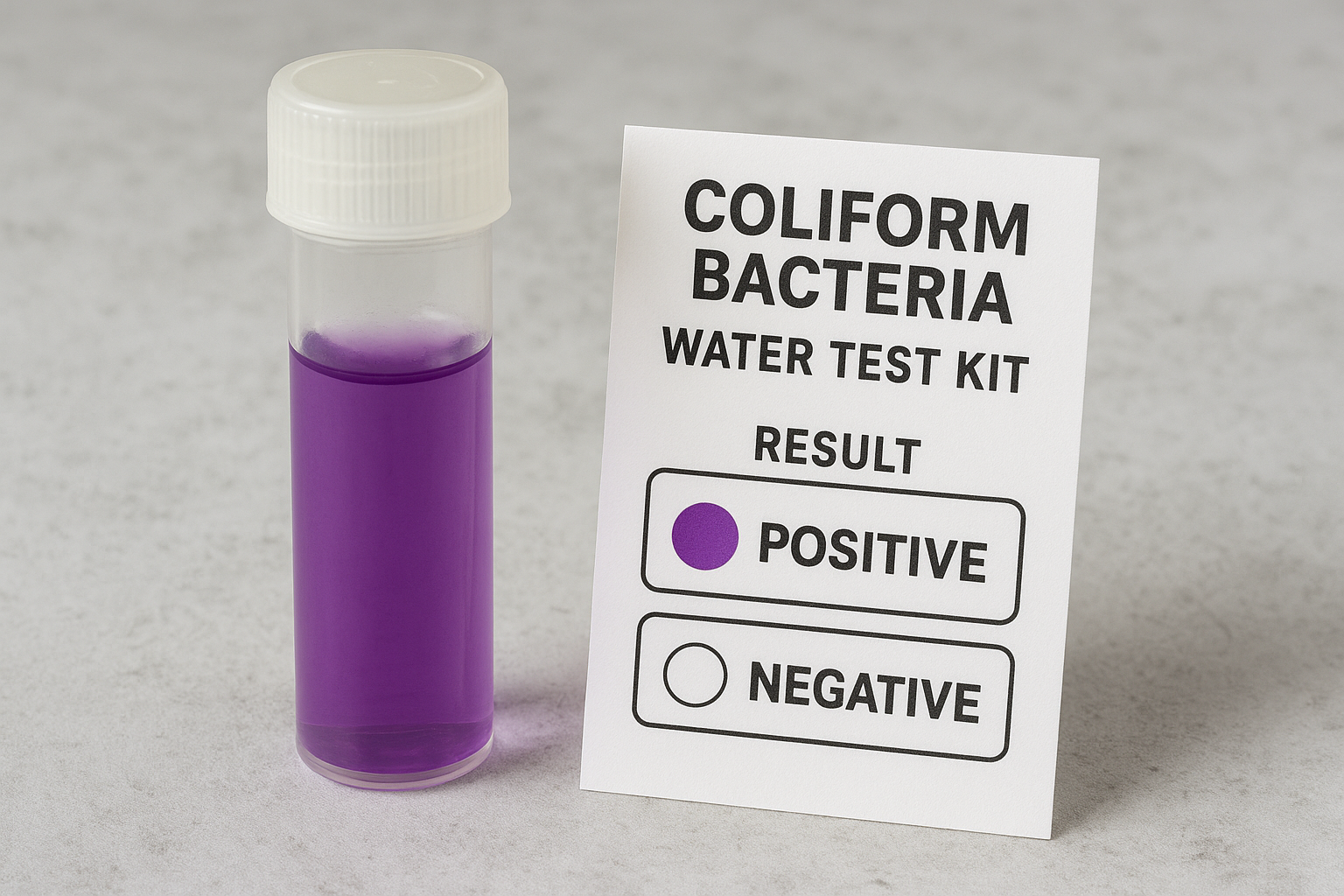

- Bacterial contamination that returns after treatment: If coliform bacteria keep appearing despite shock chlorination, surface water may be entering through a compromised seal

- Water quality changes after rain: Turbidity, color changes, or odors appearing within 24-72 hours of heavy rainfall suggest surface water intrusion

- Seasonal quality variations: Water that's good in dry months but problematic during wet season indicates seal issues

- Nitrate levels that fluctuate: Rising nitrates may indicate agricultural runoff entering through the annular space

Physical Signs

- Settling around the wellhead: Ground sinking around the casing suggests grout voids below

- Visible gaps at the surface: Any visible space between the casing and the surrounding concrete or soil

- Cracked or deteriorated surface seal: Damage to the concrete pad around the well

- Water ponding near the wellhead: Standing water at the base of the casing can eventually find its way down

Annular Seal Repair Options

If your well's seal has failed, several repair options exist depending on the location and severity of the problem:

Surface Seal Repair

If the failure is limited to the top few feet, excavating around the wellhead and regrouting the surface seal may be sufficient. This involves digging down 3-5 feet, cleaning the casing, and applying new cement or bentonite grout with a proper concrete surface seal.

Cost range: $500-$1,500

Pressure Grouting

For deeper seal failures, grout can be pumped under pressure through ports drilled in the casing or through a tremie pipe placed in the annular space. This forces sealing material into voids and cracks in the existing grout.

Cost range: $1,500-$4,000

Well Liner Installation

A smaller-diameter casing can be installed inside the existing casing, creating a new sealed system. The space between the old and new casing is then grouted. This approach works well when the original casing is deteriorated but the well is otherwise sound. See our well casing repair guide for more details.

Cost range: $3,000-$8,000+

When to Consider a New Well

Sometimes repair isn't practical. Consider drilling a new well if:

- The casing is severely corroded throughout its length

- Multiple repair attempts have failed

- The well has other significant issues (low yield, pump problems, etc.)

- Repair costs approach 50% or more of new well costs

- The well doesn't meet current code requirements and can't be brought into compliance

Cost Expectations for Well Grouting

| Service | Description | Typical Cost |

|---|---|---|

| New well grouting | Standard annular seal during well construction | $500-$2,000 |

| Surface seal repair | Excavation and regrouting of top 3-5 feet | $500-$1,500 |

| Pressure grouting | Injecting grout into existing seal voids | $1,500-$4,000 |

| Well liner | Installing casing inside existing casing | $3,000-$8,000+ |

| Seal integrity testing | Video inspection or pressure testing | $300-$800 |

Frequently Asked Questions

What is well grout and why is it required?

Well grout is a cement-based or bentonite material that fills the annular space between the well casing and the borehole wall. It creates a watertight seal that prevents surface water, contaminants, and bacteria from traveling down the outside of the casing and entering your aquifer. California requires proper grouting on all new wells and has specific depth and material requirements to protect groundwater quality.

How deep does well grout need to go in California?

California requires the annular seal to extend from the ground surface to a minimum depth of 50 feet, or to the top of the first impervious stratum below the water table, whichever is less. In areas with known contamination or special geological conditions, local enforcing agencies may require deeper seals. The grout must also extend at least 20 feet into any impervious formation if one is present.

How can I tell if my well's annular seal has failed?

Signs of annular seal failure include: sudden changes in water quality, especially after heavy rain; bacterial contamination that keeps returning after shock chlorination; visible gaps or settling around the well casing at ground level; water quality that worsens seasonally; and positive coliform tests without an obvious source. A video inspection or pressure test can confirm seal integrity if you suspect problems.

Can a failed annular seal be repaired without drilling a new well?

Yes, in many cases a failed annular seal can be repaired. Options include pressure grouting to fill voids in the existing seal, installing a well liner inside the existing casing, or excavating around the wellhead to repair the upper portion of the seal. The best approach depends on where the failure occurred and its severity. However, if the casing itself is severely corroded or damaged, well replacement may be more cost-effective.

How much does well grouting or seal repair cost?

Well grouting costs vary based on well depth and conditions. For new wells, grouting typically adds $500-$2,000 to drilling costs. Seal repairs range from $800-$3,000 for surface seal repairs and pressure grouting, while comprehensive re-grouting or liner installation can cost $3,000-$8,000+. These costs are significantly less than the $15,000-$40,000+ cost of drilling a new well, making repair a worthwhile investment when feasible.

Concerned About Your Well's Seal?

If you're experiencing recurring water quality problems, notice settling around your wellhead, or want to verify your annular seal is intact, we can help. Our team performs seal inspections, repairs, and complete well rehabilitation throughout San Diego and Riverside counties. Protect your water supply—and your family—with a properly sealed well.